How will next generation battery technology change the EV market?

What have Tesla’s battery technology successes got to do with the bicycle business and long term sustainability of our transport? Ellis Blackman argues that these are developments we should be watching closely…

Over the last few years, Tesla have dominated the word with their EV’s, we all know about their cars and their truck, but, they have also been putting a lot of time and effort into other electric vehicles, like an ATV, Vertical Take Off and Landing (VTOL) plane, drones and many other very interesting things.

However, the key for us, is their research in developing battery technology.

Now for the commercialisation of a VTOL Taxi or, for the logistics industry to use EV’s fully and for more widespread use of electric vehicles we will need a few things.

- Better battery energy density. (Longer Lasting Batteries)

- Higher number of charging cycles. (More charges before the battery dies)

- Increased energy storage, both wholesale and in our homes. (power walls in homes and power storage units worldwide, similar to the Australian unit produced in 2017)

- Faster charging facilities.

Earlier this year Tesla’s battery research group in Canada released a paper that shows how they are forging a path to a next-generation battery cell, this cell will have breakthrough energy density allowing the idea of a green world to become a reality.

Reading into the paper there are quite obviously some hurdles to overcome, however the research does identify bottlenecks and points to solutions.

Jeff Dahn (Professor in the Department of Physics & Atmospheric Science and the Department of Chemistry at Dalhousie University) and his team at their Canadian lab have long been conducting leading battery research, but over the last four years, have been proceeding in partnership with Tesla.

Focusing on improving the current generation of Lithium Ion batteries, they have also been looking at new technology that does not just slightly improve batteries but changes them completely.

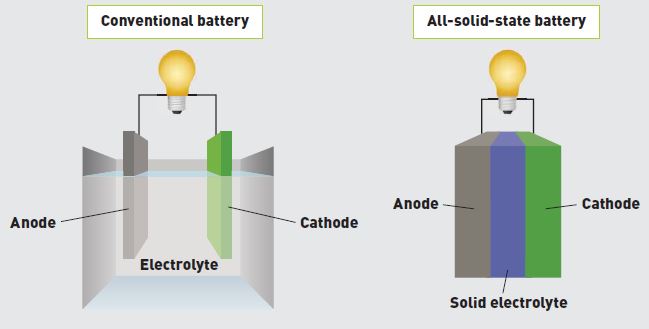

A lot of people (myself included) think that the future of battery tech was in solid state batteries, this is due to the fact that if you remove the liquid electrolyte, you could extrude sections of the battery, very similar to how you process plastics. Meaning that it would not only be significantly safer to manufacture, but it would also reduce costs per KWH significantly. (Hyundai have recently invested very heavily into this technology).

But, Dahn and Tesla’s research shows a very different path – Anode free, Lithium pouch cells with dual-salt LiDFOB/LiBF4 Liquid Electrolyte.

In a paper that was produced last year, Dahn suggested their new batteries would have a significantly higher energy density and don’t require a new method of manufacturing, however there was a few issues with longevity of their units, circa 90 cycles, which is nowhere near what is required for any commercial application, be it bikes, cars, trucks or otherwise.

However, in a paper now released by Dahn & four other Tesla Employees called “Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis” published in the scientific journal Nature, they have not only identified the problems with the cells longevity, but also introduced corrective actions.

However, in a paper now released by Dahn & four other Tesla Employees called “Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis” published in the scientific journal Nature, they have not only identified the problems with the cells longevity, but also introduced corrective actions.

They wrote “Recently, we demonstrated long-lifetime anode-free cells using a dual-salt carbonate electrolyte. Here we characterize the degradation of anode-free cells with this lean (2.6 g AG-1) Liquid electrolyte. We observe deterioration of the pristine lithium morphology using scanning electron microscopy and X-ray tomography, and diagnose the cause as electrolyte degradation and depletion using nuclear magnetic resonance spectroscopy and ultrasonic transmission mapping. For the safety characterization tests, we measure the cell temperature during nail penetration”.

In their testing they found that with their dual-salt electrolyte there’s an inactive matrix in-situ of dead lithium that forms large dense lithium columns inside, forming an ideal lithium morphology.

Their paper not only shows the identification of bottlenecks but also how to improve the life of the lithium metal anode-free cells to 200 cycles, which although still not good enough for commercialization, is a huge step in the right direction.

If Tesla keeps pushing in this way, battery cell efficiency will go through the roof, meaning that not only will we have high quality cells available to us, but we will also then be able to properly utilise powerwall(s) in our homes, our work and at sites all over the country and world.

In theory, this would mean that we could store our own solar energy better, or in the case of commercialisation, energy companies could store the wind, solar and tidal energy they produce at off-peak times saving it for when demand is increased, rather than letting it go to waste. Energy costs would plummet and, as there would be public confidence in both the range and longevity of EVs, there would most likely be a significant shift in vehicular buying habits. Especially if it was combined with a governmental incentive, similar to the current German offering.

But, how does this change the world you say? Well, by saving the energy we produce, both green or otherwise, rather than it going to waste, we (In the short term) would only need to use fossil fuels to top up our energy demands, rather than using it to provide the bulk of them.

This dream isn’t actually too far away, as back in 2017, Tesla helped the Australian Government with a then record breaking 150 MWH storage facility in southern Australia, co-locating with the Hornsdale wind farm. After six months of operation, the Hornsdale Power Reserve was responsible for 55% of frequency control and ancillary services in South Australia. By the end of 2018, it was estimated that the Power Reserve had saved A$40 million in costs, mostly in eliminating the need for a fuel-powered 35 MW Frequency Control Ancillary Service.

Fast forward to 2020 Tesla and PG&E have recently broken ground on a record breaking energy storage facility in Monterey, California, that when complete will be the largest installation in the world. The battery park will be able to churn out 730 megawatt hours (MWH) of energy to the grid at a maximum rate of 182.5 MWH for up to four hours. Tesla and PG&E will then upgrade the system’s capacity shortly after completion to 1.2 gigawatt-hours which according to Tesla, will power every home in San Francisco for six hours. (According to the 2019 census, there are 359,673 households and an estimate of 881,549 people)

All this is well and good, but how will it benefit cycling? Well, if batteries are better and cheaper, e-Bikes will go further for less money, meaning that your general layman will be more likely to buy an e-Bike and use it for everyday cycling, eventually realizing its potential for other duties.

Nevertheless, the key thing is perhaps this; more courier / mail companies will use electric vehicles more as the battery technology enhances the already strong viability in a business case. Your postman may be equipped with a bicycle again, your community brewery or butcher may start to use a cargo bike for local deliveries, and the more bikes we see on the roads, the more normal it becomes. The higher we regard them, the more we use them and the more we rely on them rather than a car.

Related: European Commission creates €3.2 Bn fund to develop battery technology.

Photos: Cube / Spring8