Cycle Inspect carbon inspection gear could give bike workshops a niche

Market data is predicting a growth in sales of carbon fibre bikes of around 15% per year to 2025, but what happens to the bike frames should they fracture? Cycle Inspect has introduced a new retail-based tool for diagnosing such issues…

59.4 million carbon fibre framed bikes will land in the marketplace by 2025 if the aforementioned compound annual growth rate of 15% is accurately forecast. For anyone who’s given a moment’s thought to end of life of such products that’s a terrifying amount of carbon that could very well end up in landfill. Repair and indeed diagnostics ahead of that are not commonplace in the market, consumers instead tempted by a new model year.

Lighter, stiffer, increased comfort – the bike world’s marketeers have worked miracles in keeping the notion of N+1 rolling; that is the formula that describes our need to always add one more bike to the collection. But what if we could be more responsible and repair a notoriously tough to work with material and at bike retail level? First, we would need to diagnose accurately a sometimes hard to detect problem, that is the initial material fracture.

Cycle Inspect is a new to market business stemming from Tasmania, but already present in the US market with its own diagnostic tooling and software, which is built to aid trained professionals in assessing suspected carbon fibre damage via ultrasound. It is now looking for international partners who wish to become specialists in this thus far niche service.

“From our own survey data, we have found that 74% of cyclists would prefer their trusted local bike mechanic to conduct inspections so we see retail partners as our primary distribution network. Our vision is to develop a global network of inspection hubs through our retail partners, but for these retail partners to determine how the service is positioned, priced and presented to their customers,” Founder Michael Briggs tells CI.N.

At a time when bicycle retailers are fast adding products and services outside of the traditional, Briggs’ idea is to further embed with customers the notion that the local bike shop truly is a invaluable and not just there to sell you a shiny but expensive bike when a sustainable alternative now exists.

“Firstly, we want to provide detailed inspection profiles of bicycles to reduce the likelihood of ‘premature obsolescence’ – i.e. where a carbon bike is deemed to have reached the end of its ‘safe life’ too soon. Carbon is a remarkably strong material that can last decades, if cared for and repaired well. We have also been in discussions with a university here in Australia regarding the application of novel recycling techniques,” says Briggs of the conversation around repairing and reusing as part of a drive to sustainability.

The conversation has never been livelier on this point and indeed elsewhere in this issue you’ll find scrutiny of big label sustainability reporting, while during January mechanics in the United States scored column inches around the globe with a petition calling for an end to manufacture of the ‘bicycle shaped object’; that is a cycle that can reasonably be considered to be designed with little care for life cycle and build quality.

Carbon fibre bikes are rarely in this category of ‘BSO’ and so are very much worth repairing. It is the myth that carbon is essentially irreparable, or that the costs of doing so will be prohibitive, that stops many consumers exploring the idea.

As for spotting the tell-tale signs, it certainly takes a trained eye. That said, evident signs of delamination can be a clue, which upon further inspection can reveal a fibre breakage. Many of damage and defects within carbon structures cannot be seen on the surface, or detected by the common tap test that many cyclists might be familiar with. Some cyclists would inspect their bicycle visually after a crash or impact, but the damage is often actually transferred beneath the surface while the exterior remains intact. For this reason those embedded in the high-end bike world have come out endorsing the idea behind Cycle Inspect and wishing the upstart well.

“We’ve been luckily enough to gain support from a number of reputable organisations, institutions and public figures, which has been an amazing vote of confidence for us as well as a sign that there is widespread support for the introduction of a standardised solution for inspection and risk assessment in the industry,” says Briggs.

Phil Liggett was an early supporter, while organisations like Bike Exchange and Bicycle Network have also identified a need in this space. Deakin University, who Cycle Inspect partnered with for its initial research back in 2019, has offered support for the work the business is doing and the importance of raising awareness of the hidden dangers of damaged and defective carbon.

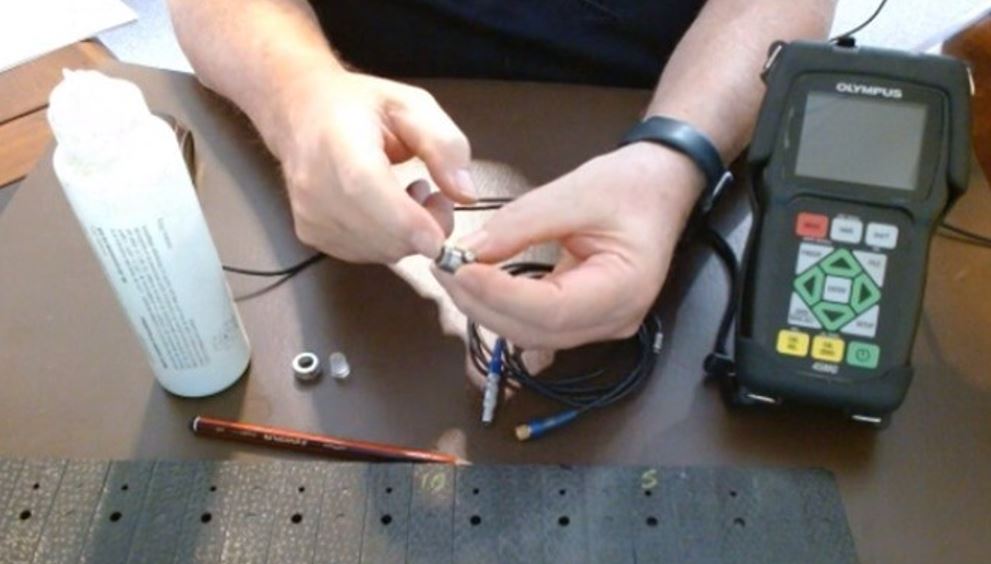

“We have undergone several trials with mechanics at all levels – and have been encouraged by the speed at which trainees have understood information presented to them, grasped the important technical skills, and applied this to their inspection,” says Briggs of the hardware and software package that Cycle Inspect is now seeding with retail partners and brands.

So, how does it work?

So, how does it work?

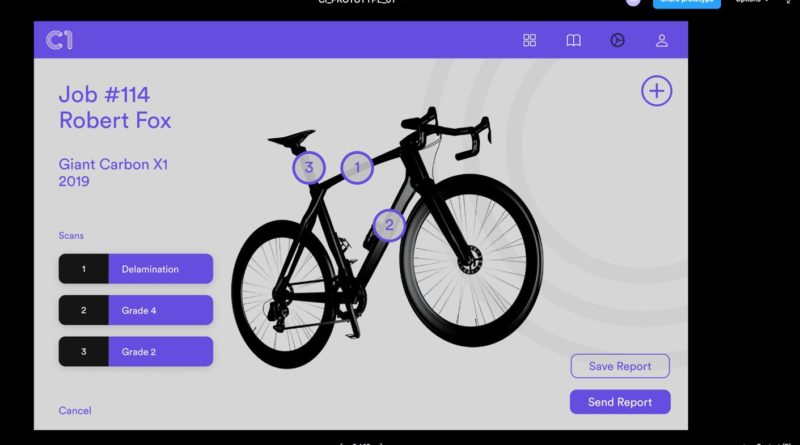

“Essentially, an inspection attempts to identify any damage or defect in a carbon bicycle part i.e. anything that is likely to be different than what the manufacturer intended. The software compiles approximately 15 data points, including objective scan data and contextual information captured directly from the customer. The algorithm (patent pending) sits behind this and assesses these inputs, offering an objective risk output and suggested courses of action instantaneously,” explains Briggs.

Once scanned, those algorithms will feed data into a dashboard where risk assessment software can consistently and accurately automate the diagnostic process. For those who shudder upon hearing the word algorithm, there’s nothing complicated about the process and training is provided via a platform that provides foundational theory and content covering composite materials and repair, ultrasonic theory and ultrasonic NDT (non-destructive testing).

“Successful completion of Cycle Inspect virtual training (which includes both theoretical and practical components) sees trainees granted with a ‘provisional accreditation’ where inspections are monitored and feedback given prior to a ‘full accreditation’ being given. Course content is aligned to international standards, however our accreditation is the first of its kind,” Briggs says, adding “We believe carbon inspections should be built into general service offerings and should also precede every sale of a used bicycle.”

At a time when global supply of bicycles is turbulent and consumer spending tightening, being able to diagnose and repair carbon fibre frames and forks may well prove to be a preferential option for both dealer, consumer and the environment.

Briggs summarises: “The main advantage of our solution is that shops have the ability to determine whether a bike or component actually requires repair – saving time, shipping costs; and ensuring a more positive customer experience for their clients. Our system provides some guidance on what to expect as part of the repair process and, where possible, referral to reputable repairers in the area.”

Now for the important bit, what’s this going to cost a workshop keen to offer the service?

Cycle Inspect put the total package at AUD $1,500 (about £795, at the time of writing), that is including all eLearning, procedure documentation, live webinars and ongoing feedback/reviews, plus the accreditation once ready. Retailers have the option to purchase the technology package upfront, or to opt for a monthly lease for $100 per week. Lastly, an ongoing fee of $25 per week is charged for unlimited access to Cycle Inspect’s web-based risk assessment platform.

“We have developed a very cost-effective solution in which retailers/workshops can begin making a profit with as little as one full bicycle inspection, or just a couple of spot checks per week,” concludes Briggs.

UK bike businesses are welcomed to get in touch to become among the first to offer the service in the country. Email Micheal here.

www.Cycleinspect.com

Related: Could bio-based carbon fibre help the bike industry clean up?