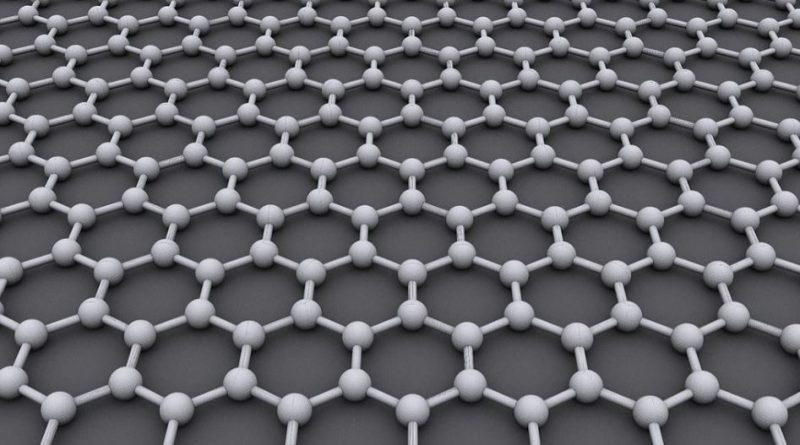

Mass production of Graphene moves a step closer with “cost effective” breakthrough

A Singapore research team has developed a new Graphene production method that requires 50 times less solvent than traditional methods and one that opens the door to larger-scale production.

Pioneered by a team at the National University Singapore, the team set about creating a more sustainable method to harvest what has been dubbed a wonder material by many.

The newly developed method is said to have been discovered by exfoliating pre-treated Graphite under higher than normal alkaline conditions, something that triggers flocculation. This process prompts the Graphene layers to cluster together to form a slurry and without the need to bolster the solvent content. The method also prevents reattachment to the Graphite via a newly introduced electrostatic process.

The slurry can also be used directly to 3D-print conductive Graphene aerogels, an ultra-lightweight sponge-like material.

Professor Loh Kian Ping from the Department of Chemistry at NUS Faculty of Science, who is also the Head of 2D Materials Research at the NUS Centre for Advanced 2D Materials, led the research.

He said: “We have successfully demonstrated a unique exfoliation strategy for preparing high quality Graphene and its composites. Our technique, which produces a high yield of crystalline Graphene in the form of a concentrated slurry with a significantly smaller volume of solvent, is an attractive solution for industries to carry out large scale synthesis of this promising material in a cost-effective and sustainable manner.”

The research was conducted in collaboration with Fudan University and the findings were published in scientific journal, Nature Communications, earlier this year.

Put to use in the bike business by the likes of Rolo, Vittoria and Dassi, among others, Graphene’s properties lend well to selected areas of bicycle industry manufacturing, from smart clothing, right through to the kind of carbon mixing work undertaken by the aforementioned bike labels.

The conventional method for Graphene production makes use of sound energy or shearing forces to lift layers from Graphite. These are then dispersed in large volumes of solvent – a sticking point from an eco viability point of view. Using less solvent can see Graphene layers reattach to the Graphite. This means that present techniques had required around one tonne of organic solvent to lift one kilogram of Graphene.

Upon mixing Graphene with Vittoria’s tyres, marketing spokesperson Frank Levering explained to CI.N the benefits: “Think of vase full of marbles, that’s carbon. Graphene is the sand that fills the jar, adding an immense amount of new properties to an already excellent material.”

China, which is rich in raw Graphite, has invested heavily in exploring the new material’s potential.