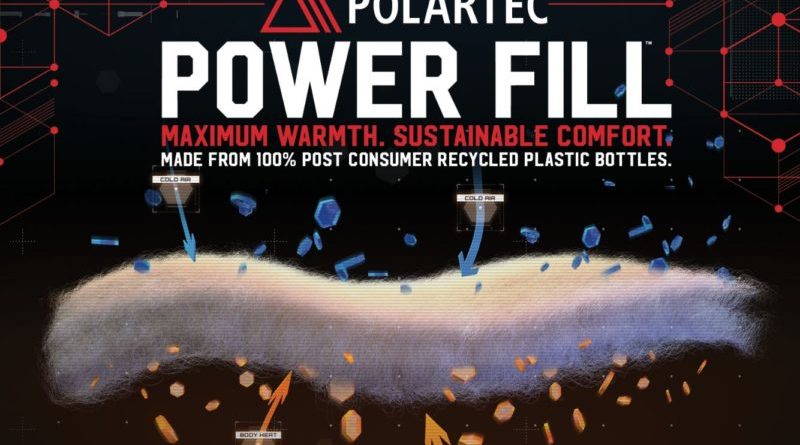

Polartec introduces 100% post-consumer recycled Power Fill Insulation

Outdoor clothing manufacturer Polartec has announced the creation of a 100% post consumer recycled insulation fibre.

Having introduced an 80% recycled content material one year ago, the manufacturer had set itself the target to hit 100% in a few years’ time. The business has, however, accelerated the eco-friendly development and will now make available Power Fill Insulation in 80 and 100 g/m² weights, with the Oeko-Tex Standard 100 certification.

For brands interested in utilising the upcycled fibres, Polartec Power Fill is said to be warm, lightweight package insulation that is hydrophobic, fast-drying, and highly compressible. Power Fill is made of proprietary hollow fibers that are bonded together through a process that reduces environmental impact, while simultaneously providing superior insulating properties, durability and hand.

This unique process also results in a more stable layer, removing the need for disposable scrims, stabilizing agents, or carriers used by some competing insulations. Unnecessary scrims add weight and may not be made from recycled content, possibly skewing warmth-to-weight ratios and recycled content measurements. By eliminating the need for a wasteful scrim, Polartec Power Fill is warmer for its weight, reduces cold spots and aesthetic changes from migrating fibers, and opens up new design possibilities.

As utilised by outdoor giants such as Rapha, Sportful, Patagonia, Rab and many more, Polartec has long held ambitions to create a cleaner business and recently announced that it had upcycled one billion post consumer plastic bottles into hundreds of fabric styles.

“Finding sustainable solutions is a core objective of our science of fabric,” says Gary Smith, Polartec CEO. “We’re proud to have ‘cracked the code’ required to produce premium quality insulation from 100% PCR materials.”