German Aerospace Center developing fuel cell with implications for big business cargo bike use

The German Aerospace Center is currently developing a “fuel cell range extender” that can completely substitute the battery of an electric bike and in particular has big implications for electric cargo units.

In development at present, the prototype “makes sense for applications requiring 2 – 5 kWh”, CyclingIndustry.News is told. It is for this reason that the technology is targeted at the electric cargo arena where the extra power may be needed to haul heavier loads through the urban sprawl.

Björn Offermann of the German Aerospace Center told CI.N: “The FCREX is designed as module that fits in different frame concepts of cargo bikes and can substitute the battery. Batteries are quite a good solution for the range of between 0,5 and 1,5kWh, but this cell offers a greater level of power. There are none of the issues found with batteries, such as short life cycles and issues with low temperatures. All things considered, this is a great solution for commercial transport.”

Working in the business of fuel cell technology for over 30 years, the Aerospace Center has teamed with the Institute of Engineering Thermodynamics on this project. There are plenty with interest in the technology’s development, with whom the center is forging links.

Working in the business of fuel cell technology for over 30 years, the Aerospace Center has teamed with the Institute of Engineering Thermodynamics on this project. There are plenty with interest in the technology’s development, with whom the center is forging links.

“The whole project is supported by the Department for Technology Marketing who take care that we always keep the focus on the market,” says Offermann. “Therefore, we also involved the design bureau IDberlin. With their outstanding expertise in this field, they solve the task of finding a design that takes the requirements of a module with fuel cell technology into consideration and which also show that this is latest technology.”

The end game is to see the technology feature in a new class of urban mobility, with commercial cargo bikes identified as the perfect fit to begin with.

“Fortunately, the feedback from potential users is quite positive,” says Offermann. “As we need economies of scale and thus a certain quantity, we are currently in exchange with the bigger postal service operators for a common validation project next year. Even so, further users that are really interested to take the step to hydrogen technology are always welcome. But following our roadmap, the next work package in terms of collaborations is now the identification of potential manufacturer of this technology, or parts of it. The German Aerospace Center has neither the capacity nor the mandate to produce anything of scale. Thus, we look forward to find industry partners with strategic focus on that technology.”

A Dutch car producer is one such business to take an interest thus far, so a production partner may not be far off, we’re told.

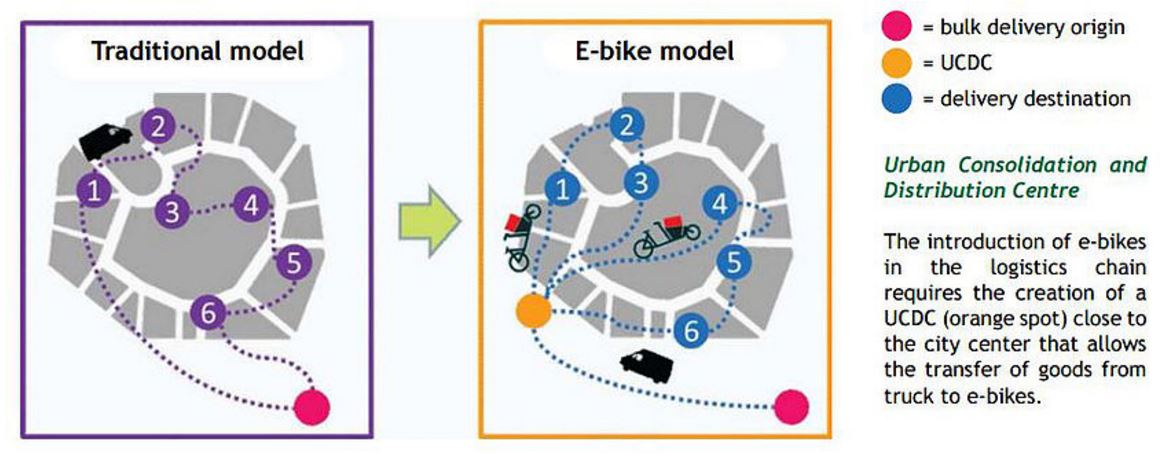

Outlining that cities must adapt how they manage deliveries and movement of people, evidence strongly suggests that switching to cargo style bikes for last mile deliveries can make not only sense in efficiency, but also business sense. “In almost every case,” a saving can be made with last mile cargo bike delivery found a Pro E-bike study published last year.

suggests that switching to cargo style bikes for last mile deliveries can make not only sense in efficiency, but also business sense. “In almost every case,” a saving can be made with last mile cargo bike delivery found a Pro E-bike study published last year.

Today, 75% of the Europeans are living in cities and suffer from air and noise pollution, as well as from traffic jams. The transport sector in cities is primarily a combustion engine affair. Currently such engines cause 50% of the emissions and 30% of the vehicle kilometers and is thus one of the major contributors to pollution presently blighting urban spaces.

“The character of last mile deliveries has fundamentally changed,” explains Offermann. “Due to e-commerce, people are ordering more and more online direct to their letterboxes. It makes no sense to use the old and big combustion engine vehicle concepts for these new requirements. Cargo bikes can carry up to 300 kilograms and reach higher average speeds than vans within cities. In order to drive efficient delivery chains, maybe with chilled cargo and heated cabins, in hilly regions, for 8 hour shifts, vehicles need more energy than modern batteries can provide at a viable price.”

It is for these reasons, says Offermann, that a smarter alternative is needed.

“By combining smart cargo bike concepts with our fuel cell technology, we provide veritable answers for this issue. The objective of this project is to turn this technology into a German Aerospace Center spin-off that brings the FCREX to broad application and reduce considerable part from the fine dust pollution and traffic jams in European cities,” he says.

The most pressing issue from an industry and end-users’ perspective is cost and despite the increased power, there are some promising signs that the cell will deliver strong cost to benefit ratios.

“Tom Assmann from the University of Magdeburg did the math and calculated the total costs of ownership depending from the required amount of energy in comparison to batteries. He assumed economies of scale of a production of 1,000 FCREX. The result shows, that from an economic perspective our fuel cell technology compares favorable against batteries from 2kWh onwards. This is the outlook if our technology comes into broad application.”

Cost aside, the fuel cell brings to the table rapid charge times ranging just two to five minutes, depending on the cell size. At present, cells ranging 2 to 5kWh are planned.

“How far you can drive with the provided energy depends from many factors. But if you take today’s batteries with 0,5 – 1,5kWh as comparison, you can imagine how far cargo bikes can go with the FCREX,” adds Offermann.

So, what obstacles has the Center still got to overcome with this technology?

“We have to deal with the insufficient hydrogen infrastructure that was a veritable showstopper in the past,” explains Offermann. “We are still not counting on enough hydrogen stations coming up in the near future. Currently, there are interesting alternative developments. We are in exchange with Airbus and Linde who have developed a small, efficient and payable electrolyser with compressor that can produce and provide enough hydrogen for a fleet of cargo bikes.

“Alternatively, Dr. Marcus Tegel from the Fraunhofer IFAM institute has developed a paste – PowerPaste – that reacts with water to hydrogen and provides a very high energy density. We plan validation projects with both technologies next year. Thus, together with our partners we can provide a holistic concept that enables cargo bikes to deliver a much more efficient logistic chain. Energy is now longer the limiting factor.”

Industry manufacturers with a hand in the commercial cargo bike world are now invited to make contact, should they feel the FCREX has potential for their productions.