Ambition for bike manufacturing and assembly hub in Scotland outlined

Scottish investment into the cycling market looks set to be furthered with an ambitious launch of a new assembly and bike manufacturing hub put forward by a company set up under the Route Assembly banner.

CyclingIndustry.news spoke this week with Founder Ian Byrne, a former Reid Bikes assembly worker, who eventually hopes to mirror the success of European manufacturing and assembly districts set up in places like Portugal.

CyclingIndustry.news spoke this week with Founder Ian Byrne, a former Reid Bikes assembly worker, who eventually hopes to mirror the success of European manufacturing and assembly districts set up in places like Portugal.

“Whether we can go in that direction or not remains to be seen, but someone has to take the step,” starts Ian, having committed the business to an annual assembly capacity of over 25,000 at its Glenrothes base.

“I’ve no issue with Asian manufacturing, nor assembly, but there’s also no reason why we can’t do it too and the more I’ve spoken to people the more it’s clear there’s a shortfall, particularly in assembly. Personally, we got to a point where we decided now is a good time to start going for it, so we’ve got some investment and a team and started pipelining building sites and network. I would love to hear from anyone who wants to work on the reshoring effort, even if it is not in a capacity to work directly with us. For example, somebody who could supply wheels, handlebars or anything really; I can try to facilitate putting them in touch with the relevant people. “

The ambitious project is timely in that it’s seeking to address a cluster of issues thrown up by both Brexit and the pandemic. There exists a reshoring trend with many European labels, but to narrow down why the reliance on Asian supply has in recent times come with new challenges, namely long lead times in the face of global shipping turbulence, which has been compounded by steep price increases. Then there’s the environmental cost of the logistics, something becoming incompatible with the need to clean up business.

“That’s before you get to the import tariffs and anti dumping charges. So companies end up with a fairly high MOQ, high cost on potentially lower quality bikes and lead times that can leave them out of stock for long periods of time. All of this gets passed on to the customer who needs to pay for all of those charges and delays and losses on their end. With reshoring industry you have cut out nearly all of the time and hassle of international shipping. Even cooler – I think – is the lower costs and MOQs enabling much smaller businesses become viable. Currently the death rate among eBike startups is high no matter how good their ideas are,” explains the business.

Apparently supportive, the Scottish Government is keen on projects that are big on job creation and there exist a need to reskill workers lost to other industries.

“Down south investment felt harder to find, we would be applying for funds that any industry can apply for. The Scottish Government is instead looking at each case scenario, so there exists a lot of opportunity to access funds on job creation up here. Investment in this kind of business ticks the health and fitness, climate and green mobility boxes – all the right notes for the Government,” says Ian.

This, he says, may be why companies such as Freeflow Technologies and Intra-Drive are off to a good start with investment. Add to that, Scotland’s Innovation Centre and consistent investment in cycle tourism and the ecosystem is already beginning to bustle. As with Portugal Bike Value, or India’s Hero driven Cycle Valley, a cluster of businesses can become complimentary, keeping trade within borders and steadily reducing the need for brands to ship product or prototypes across the globe.

The Route Assembly infrastructure, while a work in progress and somewhat led by the order book, is rapidly coming together. There already exists a full design facility, rapid prototyping ability, a full assembly service and manufacturing potential for frames and possibly other goods.

How did this all come together under the radar, we ask?

“Clients may lead where we invest to a degree. The first clusters of interest are largely coming from newcomers to the industry, those disruptors that are offering subscription service bikes, among others. Assembly is the key shortfall and we can do that for £45 per bike. We have quotes for equipment that will allow us to invest in where the demand lies. An interesting point outside of this is there existing some talk of putting to use recycled aerospace industry aluminium, so not only could we cut the need to ship for clients, but we could produce in cost effective and conscientious way,” says Ian.

There is an element of chicken and egg at play. While the business has investment and expects to be able to raise further, it will, for now, be selective about its partners. “They will have to have money in the bank and we will scale up to their needs,” explains Ian, adding “Our goal is to scale up a modular process in background to full bike assembly, as well as to produce high-end frames and wheels and have a production focus, but this will depend on demand.”

That’s not to say the business is not already firing, rideable product has already been delivered by Ian’s team. Contracts have been secured, but for companies looking to partner with Route Assembly it’s a pick and choose service. Some may opt just for rapid prototyping help, others for bike manufacturing.

That’s not to say the business is not already firing, rideable product has already been delivered by Ian’s team. Contracts have been secured, but for companies looking to partner with Route Assembly it’s a pick and choose service. Some may opt just for rapid prototyping help, others for bike manufacturing.

Starting with the design team, which has thus far been responsible for the bike that came to be Indiegogo’s most successful bike campaign, content creator and brother to Ian, Ciaran, says “we base our design choices on data. Using dealer networks, social media, etc., we pinpoint the concerns of the target market to incorporate that into the design.”

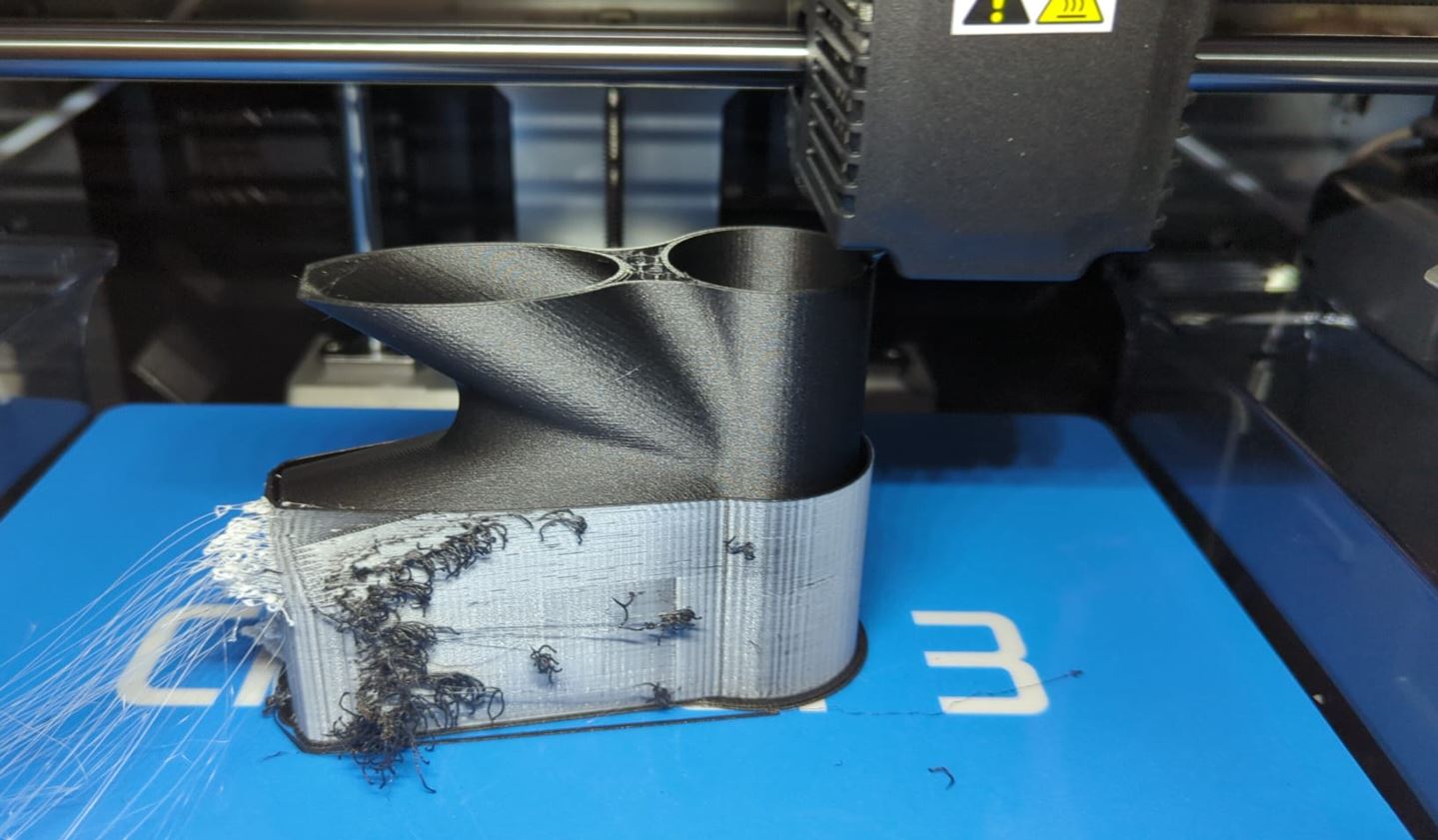

From design its off to rapid prototyping. Ciaran says “Our rapid prototyping process means that we can put out a physical prototype in as little as six weeks, for a lower cost and with a huge reduction to the carbon cost. Getting a traditional carbon fibre prototype could cost as much as £10k. We can do it for as little as £3.5k and in six weeks. Plus, using a modular design, we can make adjustments to the design much easier without the need for moulds. The process also includes the creation of AR models. On our end it’s to help confirm the look of the bike, but they are also a great marketing tool for our clients.”

Assembly and production has been spoken about, so to alleviate one other concern Ciaran adds: “We are also able to store and ship the product for our clients so they don’t have to deal with any of the logistics.”

There is a sense that the ambitious project could address another industry concern, the environmental cost of bike manufacturing and latterly shipping.

Ciaran concludes: “The shipping industry is responsible for a higher carbon output than any other industry. Add that to the fact that the primary source of bikes is mostly using coal power and it’s hard to really consider bikes and e-bikes as green products anymore. We think it’s our responsibility to make our products as green as possible. All companies really, which is why we have created our OEM services. Route Assembly isn’t just a way for us to beat these problems but a way to grow the industry domestically and allow UK and European bike brands a green and cost effective method of having their bikes produced.”